Take stock of the characteristics of rfid tags and talk about the applicable scenarios of various electronic tags.

2024-07-04

RFID electronic tag is a data carrier that is used for item identification, has an information storage mechanism, and can receive the electromagnetic field modulation signal of the reader and return the response signal. It is usually called an electronic tag, and can also be called a radio frequency card, a radio frequency tag, a radio frequency label, etc. It is the hardware main body of the RFID system together with the reader.

The basic components of RFID system include RFID electronic tags, readers, radio frequency antennas, and application software. It is an automatic identification system that uses radio frequency identification technology for data acquisition and transmission.

Under the general trend of intelligent manufacturing, RFID, as a non-contact automatic identification technology, can automatically identify target objects and obtain relevant data through radio frequency signals. RFID implementation and deployment costs are low, and data collection and transmission methods are very convenient. Enterprises are paying more and more attention.

RFID electronic tag technology

RFID electronic tag is a kind of tag that uses non-contact automatic identification technology to identify the target object and obtain relevant data through radio frequency signals, and the identification work does not require manual intervention. As a wireless version of the bar code, RFID electronic tags have the advantages of waterproof, antimagnetic, high temperature resistance, long service life, large reading distance, encryption of tag data, larger storage data capacity, and free change of stored information that bar codes do not have. The encoding, storage, and reading and writing methods of RFID electronic tags are different from traditional tags (such as barcodes) and manual tags. The encoded storage is stored in a read-only or read-write format on an integrated circuit, especially the reading and writing method. RFID electronic tags It is realized by wireless electronic transmission.

Generally speaking, the outstanding technical characteristics of RFID electronic tags are: they can identify single and very specific objects, unlike bar codes, which can only identify one kind of objects; Multiple objects can be read at the same time, while bar codes can only be read one by one. The amount of information stored is very large. Radio frequency can be used to read data through external materials, while bar codes must rely on laser or infrared rays to read information on the surface of material media.

In the process of wireless communication, the antenna is an essential component, and RFID uses radio waves to transmit information, and the generation and reception of radio waves need to be realized through the antenna. When the electronic tag enters the range of the reader antenna working area, the electronic tag antenna will generate enough induced current to obtain energy to be activated.

For RFID systems, the antenna is a crucial part, which is closely related to the performance of the system.

At present, according to the differences in antenna wire material, material structure and manufacturing process, RFID tag antennas can be roughly divided into the following categories: wound antenna, etching antenna, printed antenna, addition antenna, ceramic antenna, etc., the most commonly used antenna manufacturing process is the first three.

The manufacturing process of winding RFID tag antenna with copper wire is usually completed by using an automatic winding machine, I .e. insulating paint is directly wound on the base carrier film, and copper wire with low melting point baking paint is used as the base material of RFID tag antenna. Finally, the wire and the base material are mechanically fixed with adhesive, and a certain number of turns are wound according to different frequency requirements.

Etching The antenna etching method is also called a metal etching process. First, a base carrier is covered with a layer of copper or aluminum with a thickness of about 20mm, and a screen printing plate of the antenna male diagram is made. The resist is printed on the surface of the copper or aluminum by screen printing, thereby protecting the copper or aluminum below from corrosion, and the rest is melted by the etchant. However, due to the chemical erosion reaction used in the etching process, there are problems of long process flow and more waste water, which is easy to cause pollution to the environment, so the industry has been trying to find a better alternative.

The printed antenna directly uses special conductive ink or silver paste to print or print on the substrate. The more mature is gravure printing or silk screen printing. Screen printing saves costs to a certain extent, but its ink uses conductive silver paste with high silver content of about 70% to obtain an antenna between 15 and 20um, which is a thick film printing method with high cost.

The production process of electronic labels is mainly composed of three parts. Binding packaging, composite die cutting and post-processing links are manufactured through relevant hardware equipment. After the production of the products is completed, the products are marked, anti-static bags are installed, vacuumed and packed. In order to avoid the product exposed to the air, and to achieve long-distance transport conditions.

RFID electronic tag classification

RFID electronic tags can be divided into: active RFID electronic tags (Active Tag, active tag or active tag), passive RFID electronic tags (Passive Tag, passive tag or passive tag) and semi-active RFID electronic tags (Semi Active Tag).

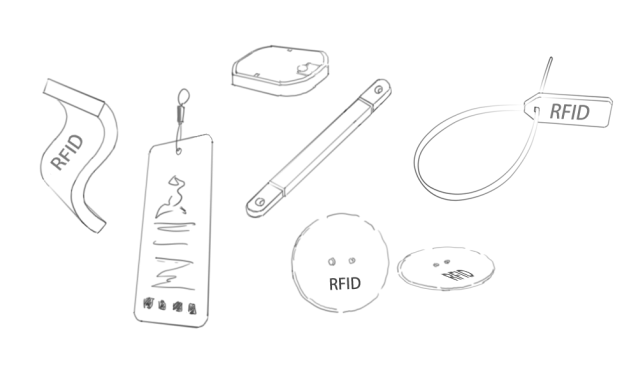

RFID electronic tags are divided into paper tags, plastic tags, glass tags, and anti-metal tags according to the packaging materials. RFID electronic tags can be divided into: film paste labels, card labels, cylindrical labels, button labels, identification labels, implantable labels and special-purpose special-shaped labels.

Some common RFID tag forms

RFID tags have many advantages

First: Unlike ordinary labels such as barcodes, which require one-to-one reading of data, RFID reading and writing devices can read and write data one-to-many on the corresponding labels.

Second: the penetration of radio frequency technology, RFID tags can be completely non-contact operation, do not need to expose the label for scanning.

Third: RFID tags have low environmental requirements and can work in various harsh environments. The tags are not easily damaged and do not affect reading.

Fourth: can be highly accurate, rapid, large-scale identification data, so it can be used for fast moving end object identification and reading.

Fifth: automation, intelligence, reduce manual operation. This is also RFID tags are called smart tags, and play an important role in intelligent construction, such as smart home, smart medical, intelligent transportation and other fields.

The difference between low frequency, high frequency and ultra-high frequency RFID and the applicable scene Low frequency RFID reader is suitable for special environments with low distance requirements, such as animal identification, vehicle access control, etc., and has the advantage of penetrating water and non-metallic materials. High-frequency RFID readers perform well in scenarios where data transmission rates are required, such as library management and electronic payments. UHF RFID readers have become the first choice in large-scale item identification scenarios such as logistics management and inventory tracking due to their long identification distance. RFID readers with different frequencies have unique advantages in their respective fields. Choosing the right frequency is very important to maximize the advantages of RFID technology. The wide application of RFID technology has brought intelligent changes to various industries, improved work efficiency and data transmission rate, and provided strong support for future digital transformation.

01

Low Frequency (LF)RFID Reader

Features:

Low frequency RFID readers typically operate in the 125 kHz or 134.2 kHz frequency range. Its recognition range is relatively short, generally about 10cm, but it penetrates water and non-metallic materials well, has less interference to the environment, and has high stability. Applicable scenarios: Low-frequency RFID readers are suitable for application scenarios that do not require high distance, such as animal identification, vehicle access control, and identification in industrial production processes. They can work stably in harsh environments and become the first choice for some special occasions.

Difference:

The main difference between low-frequency RFID readers and other frequencies is their short identification distance and relatively low data transmission rate. However, they are highly adaptable to the environment and can perform well in some challenging environments.

02

High Frequency (HF)RFID Reader

Features:

The operating frequency of the high-frequency RFID reader is usually 13.56 MHz, and its low power makes its identification range generally within tens of centimeters. High-frequency RFID technology supports one-to-many data transmission and has a high data transmission rate.

Applicable scene:

High-frequency RFID readers are suitable for scenarios that require high data transmission rates, such as library management, electronic payment, and access control. Its fast data transfer and reliability make it ideal for scenarios that require frequent data interaction.

Difference:

Compared with low-frequency RFID readers, high-frequency RFID readers have a larger identification range, but relatively lower than UHF. Its data transmission rate is fast, which can meet some application requirements for frequent data interaction.

03

Ultra High Frequency (UHF)RFID Reader

Features:

UHF RFID readers usually work in the frequency range of 860 MHz to 960 MHz, and their biggest advantage is that they have a long identification distance, which can reach several meters to tens of meters. At the same time, UHF RFID technology supports many-to-many data transmission, with high speed and high efficiency.

Applicable scene:

UHF RFID readers are suitable for applications with high distance requirements, such as logistics management, inventory tracking, vehicle identification, etc. Its long-distance identification and efficient data transmission make it the preferred technology for large-scale item identification and tracking.

Difference:

UHF RFID readers have longer recognition distances than low and high frequencies, but may be slightly inadequate in terms of environmental interference and identification near metal objects. However, its high performance makes it an indispensable technology in logistics and supply chain management.

Related News